Research Projects Spectroscopy

Establishing AI-supported closed loops for B2B textiles made from cotton-polyester blends based on chemical upcycling

The KICKup project investigates the transition between the end of product life and the recycling of new fibres by optimizing material flows using the example of textiles made from cellulose fibres and polyester.

Specifically, the focus is on B2B textiles that are processed as flat linen (bed linen, table linen, terry towels) or workwear (e.g. tunics and smocks) in industrial laundries (textile leasing) and can make an important contribution to resource conservation and environmental relief at the end of their use phase by returning them to the fiber cycle. The aim is to raise the recycling of cellulose fibers (natural and regenerated fibers) to the level of repeatable cycles.

To this end, a system is to be developed that uses artificial intelligence (AI) to automatically sort used textiles according to their material composition.

Contacts:Prof. K. Rebner (PAT), Fr. B. Boldrini (PAT) and K. Nebel (Texoversum)

Entwicklung einer automatisierten Prozessanalytik für die Digitalisierung von Misch- und Dosierungsprozessen von Kühlmittelschmierstoffen bei Werkzeugmaschinen

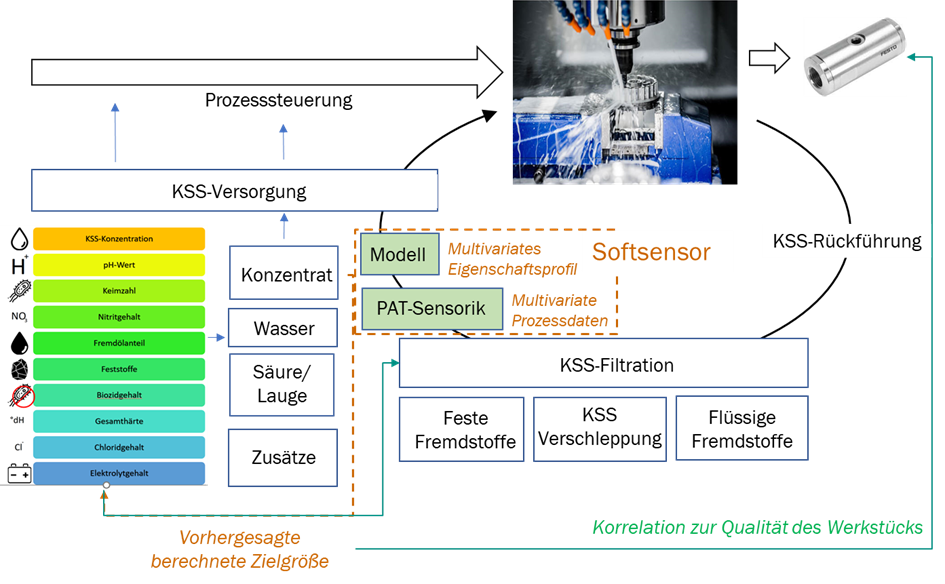

Coolant lubricants are used in the manufacturing industry for heat dissipation during milling, forming or cutting on machine tools and reduce friction between the tool and workpiece through lubrication. In addition, chips are removed by rinsing and provide corrosion protection for a better surface quality of the workpieces. The demands placed on coolants have risen steadily in recent years due to newly developed materials, modern processing machines and more complex process steps and must also comply with increasingly strict ecological regulations.

Regular checks, adjustments to the quantity ratios and filtration steps mean that cooling lubricants can be used efficiently over a longer period of time. This requires reliable and continuous measuring methods in order to detect chemical and physical changes at an early stage and to be able to counteract them. A wide variety of parameters need to be recorded and evaluated. Important parameters here are the concentration, pH value, nitrite content, foreign oil content, bacterial count, hardness of the preparation water, as well as foaming and corrosion behavior. Today, many of these parameters can only be determined quantitatively through time-consuming laboratory tests and therefore provide results with a time delay. In operational practice, samples are taken weekly and analyzed in the laboratory using simple methods or, if necessary, sent to special contract laboratories for analysis. However, if the requirements for the coolant can no longer be met, the entire mixture usually has to be replaced and disposed of. Every year, more than 700,000 tons of waste are generated in the metal and plastics industry throughout Germany (source: Federal Statistical Office, Abfallentsorgung - Fachserie 19 Reihe 1, 2019).

The project is developing a real-time capable and selective on-line method for analyzing several quality parameters of water-miscible cooling lubricant emulsions, which automatically predicts all relevant parameters continuously, suggests measures for correction and allows conclusions to be drawn about the quality of the workpieces produced by the machine tool. The frequency-dependent properties of the emulsions are measured in the optical near infrared (NIR) and by means of dielectric spectroscopy based on dipole-dipole interactions. Preliminary investigations have shown that both measurement techniques are suitable for the application, but are not selective enough on their own. With a data-driven process model of both spectroscopy techniques, the chemical and morphological changes during use are to be assessed holistically and precisely. The focus of the project is on the integration capability of quality sensors based on spectroscopy for Industry 4.0 structures and the digitalization of mixing and dosing processes.

Contacts:Prof. K. Rebner, M. Knoblich, D. Karavasili-Schreiner

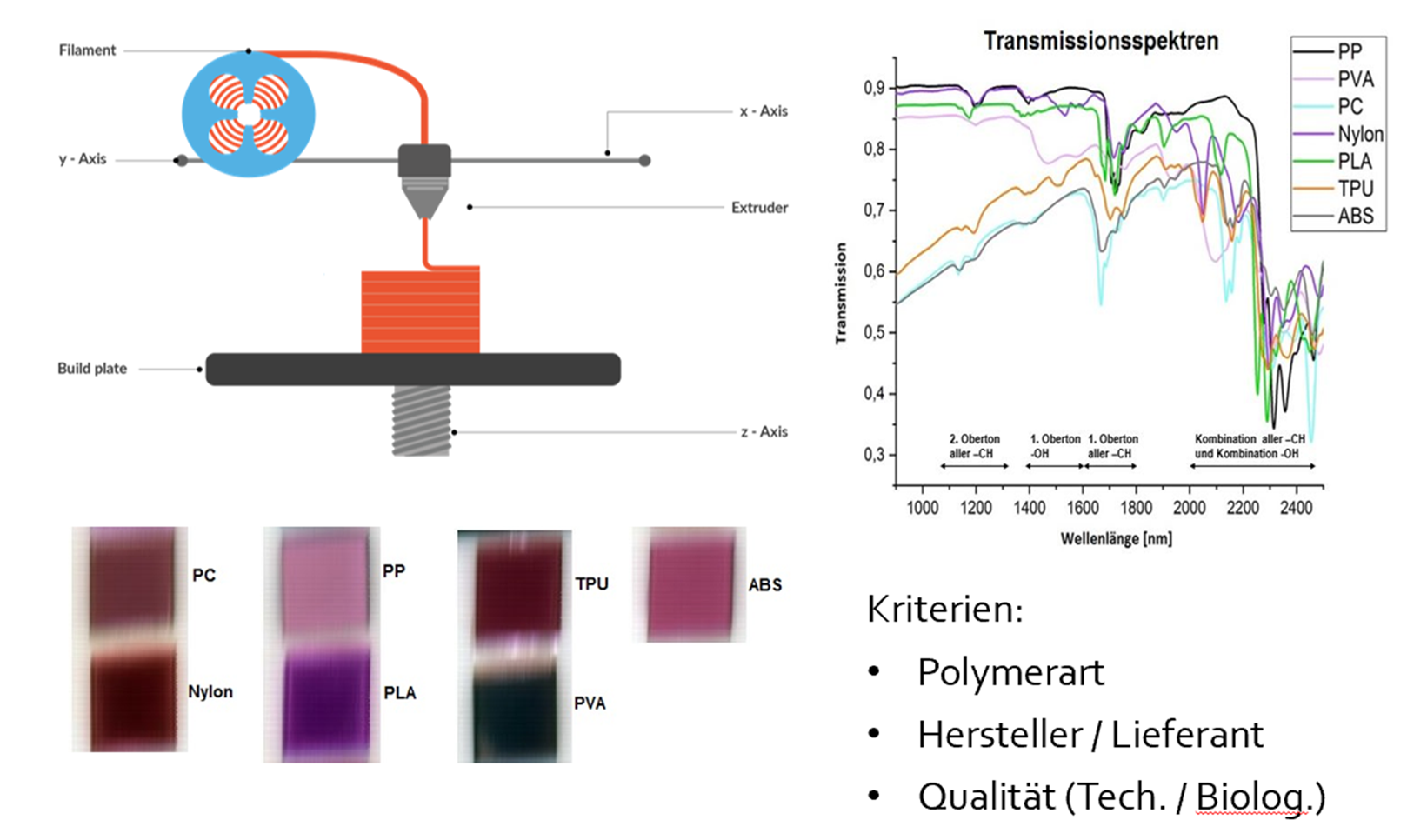

OPTICAL SPECTROSCOPY FOR 3D PRINTING PROCESS CONTROL

As part of the project, a spectroscopic measuring technique in the near infrared range (NIR) is to be developed which

- assesses the suitability of raw materials in terms of quality before printing,

- monitors the quality during printing for chemical-physical material parameters and

- enables traceability of the process conditions after 3D printing. There is currently no system on the market that analyzes the material properties based on chemical-physical properties.

Contact:Dr. rer. nat. Dimitri Golovko

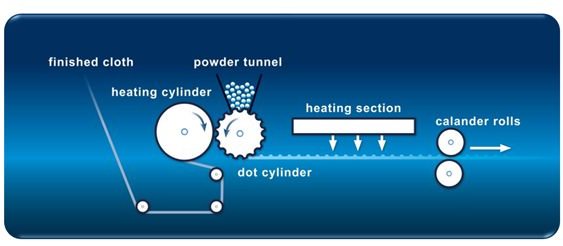

TextileSENSOR Projekt

Das Textilsensorprojekt zielt darauf ab, einen geeigneten Sensor für Textilunternehmen zu entwickeln, der ihnen bei der Identifizierung von Fremdstoffen auf ihren Textilien unterstützt. Dabei werden die Eigenschaften der Beschichtung, deren Gleichmäßigkeit und Morphologie erfasst, sowie die Effizienz der Beschichtung analysiert. Dies wird die Gesamtqualität des Textilherstellungsprozesses verbessern.

Contacts: Prof. K. Rebner, M. Ashutosh,B. Boldrini

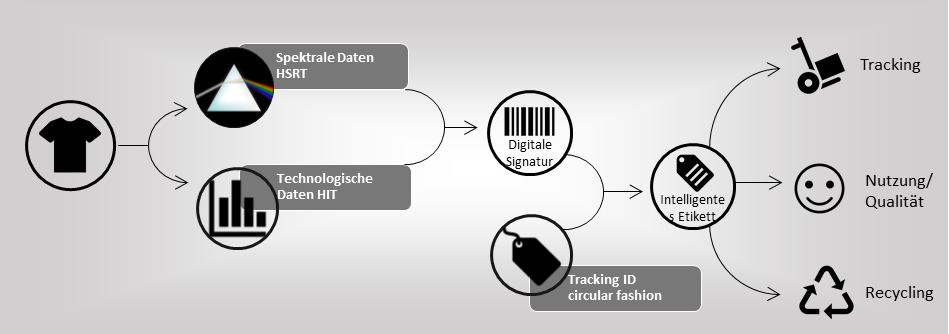

The joint project DiTex - "Resource Efficient Recycling Management"

The joint project DiTex - Digital Technologies as Enabler of a Resource Efficient Recyclable B2B Textile Industry is funded within the program "Resource Efficient Recycling Management - Innovative Product Cycles (ReziProK)". "ReziProK" is part of the BMBF research concept "Resource-efficient recycling management" and supports projects that develop business models, design concepts, or digital technologies for closed-loop product cycles.

DiTex is developing product design processes for high-quality textile recycling, piloting two closed-loop textile product lines from recycled fibres together with textile companies and evaluating their quality, resource, and sustainability. Extensive textile-physical tests, washing and wearing tests will be carried out in the one-year test phase

The Reutlingen University leads and supervises the product design process, starting with the raw material, through product adaptation, to recycling and pilot phase.

Different online spectroscopic methods will provide real-time information on chemical (material quality) and morphological (material texture) parameters of the developed textiles, which can be used to predict the content of recycled materials and the end of life in the circular process. The technological and spectral information can be condensed, evaluated, and classified using methods of the multivariate data analysis.

Contacts: Prof. K. Rebner, Mr. Dipl. Ing. Nebel (Texoversum), B. Boldrini und Mrs. Gerbig (Texoversum)

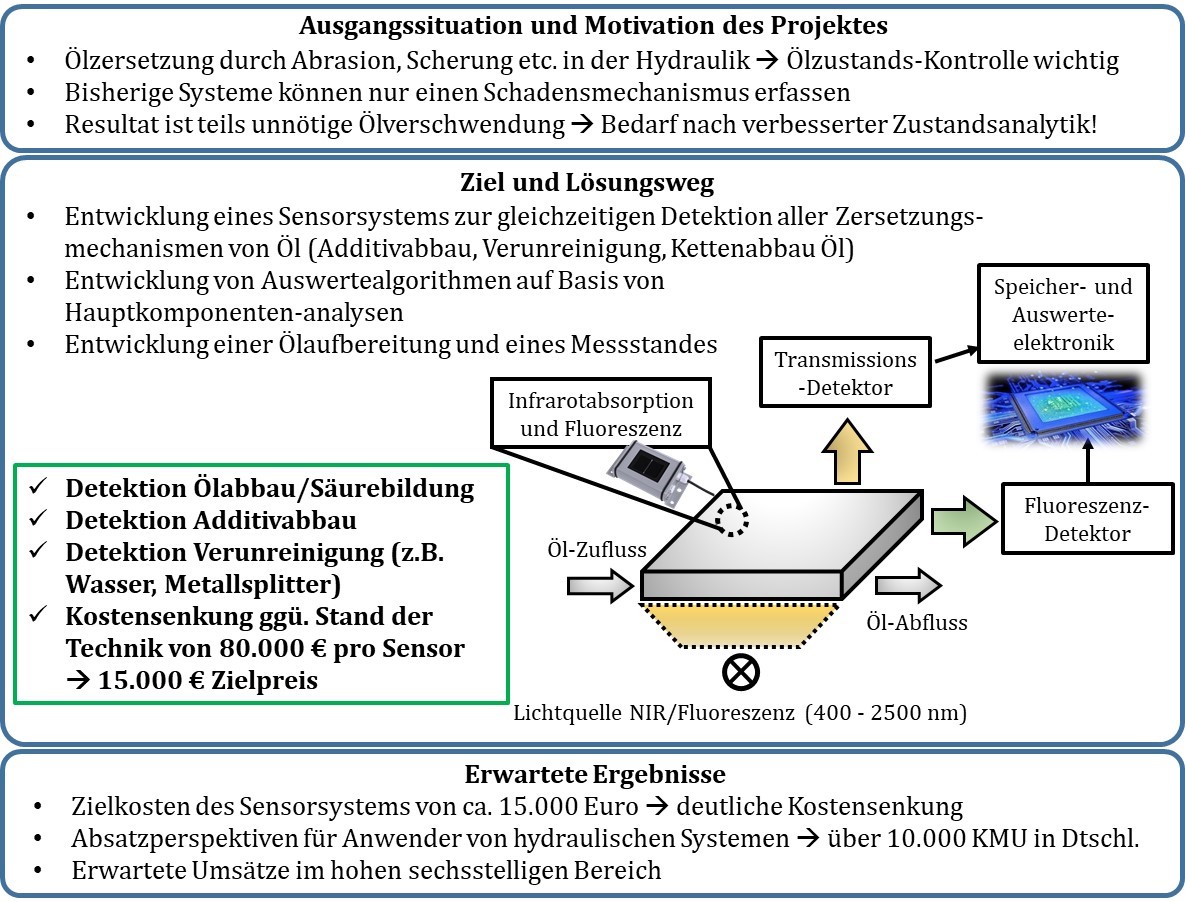

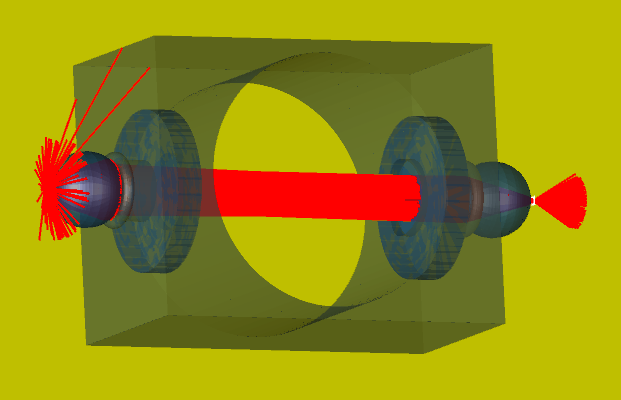

Development of a novel NIR spectroscopy sensor for continuous monitoring of the condition of hydraulic oils by simultaneous measurement of all relevant oil ageing mechanisms for reprocessing

The aim of the project is the development of a near-infrared and an optional fluorescence sensor system for the inline detection of ageing or decomposition phenomena in hydraulic oils to enable continuous quality control and, if necessary, partial recycling of the oils. In these sensors electromagnetic light from the wavelength range between 400 and 2500 nm is directed onto the oil. Two detectors measure the absorption or transmission signals as well as the radiation emitted by the fluorescence. This is intended to detect decomposition mechanisms or a deterioration in the quality of the oil, as spectral changes in the overlapping band spectra are to be expected due to damage to the oil. The sensor components in the form of the measuring cell in the order of 1 - 2 cm per spatial direction will be developed before the development of a prototype will be carried out by linking a readout electronics which is also to be developed. The sensor dimensions envisaged for this are approx. 2.5 cm ∙ 2 cm ∙ 8.5 cm. This can be linked to a bypass oil treatment system or a new type of test rig, the development of which is the subject of the last part of the project. Figure 1 shows the objectives of the project.

Contacts: Prof. K. Rebner, Prof. M. Brecht, M. Knoblich and Dr. rer. nat. D. Golovko

Miniaturized sensor system for inline/ online water analysis

The aim of the joint project is the investigation and development of a miniaturized sensor system for inline/online water analysis, which uses the possibilities and advantages of optical spectroscopy and thus allows a fast, comprehensive and meaningful analysis for a wide range of applications. The focus is on the development of a detection system for bacteria in swimming pools and water basins in wellness areas such as hotels or SPA facilities.

Using spectral methods, in particular fluorescence spectroscopy, in combination with multivariate model development from the field of artificial intelligence, the project aims to develop a cost-effective online/inline measuring cell for the detection of microbiological contamination in swimming pools. This will allow direct measurement of whether, on the one hand, there is a contamination in the pool itself and, on the other hand, whether the purification process of the water in the system is sufficient. This not only improves hygiene, but also saves time and costs through process optimisation.

Contacts: Prof. K. Rebner,Prof. M. Brecht, M. Knoblich

Development of a polyelectrolyte-based stent coating

The central goal of this project is to develop a novel polyelectrolyte-based stent coating and to research its interaction with biological systems. At our PAT center we focus on the development of analysis methods to characterize the quality of the coating obtained. For this purpose, various spectroscopic methods are combined with multivariate data analysis to determine the qualification procedure for the entire modified stent surface. This is followed by the development of an automated instrumental approach to quantify the quality standards (according to the new EU medical device regulation MDR 2017/745).

Contacts:Prof. K. Rebner and Mr. Junginger

Prozessanalytik von Getränkeinhaltsstoffen

New, innovative and sugar-reduced beverages contain a large number of different, partly natural ingredients with seasonal and local quality differences. Many of these natural raw materials exhibit a corresponding range of fluctuations, and even if the production process remains the same, they still differ in the overall composition of the beverage. For this reason, classical laboratory analysis is increasingly being replaced by fully automated process analytical technology (PAT) methods. In cooperation with an instrument manufacturer, we are developing a spectroscopic method for the above-mentioned goal, which is based on the interaction of light with matter. This results in a multimodal fluid analysis for the determination of scattering matrices.

Contacts: Prof. K. Rebner, Dr. E. Ostertag, Dr.-Ing. D. Rabus

NDSens - Development of a wet steam sensor for efficient control of cold steam chillers

In the NDSens project, a spectroscopic sensor is being developed together with industrial partners to determine the thermodynamic state of refrigerants in refrigeration plants. Here, the proportion of liquid refrigerant in the suction line of the compressor of a refrigeration plant is to be determined so that the latter does not suffer damage due to liquid ingress. By indicating this critical quality parameter, the sensor enables the refrigeration plant to be operated in a safe condition with optimised efficiency by process automation.

Contacts: Prof. K. Rebner and T. Drieschner

Prozessanalytik mittels Time-Gate-Raman-Spektroskopie für die Kontrolle und Steuerung von Prozessen in den Lebenswissenschaften

All further information you will find, on the website of the project: Find out more

Contacts: Prof. K. Rebner, Hr. Ostertag, Fr. Boldrini

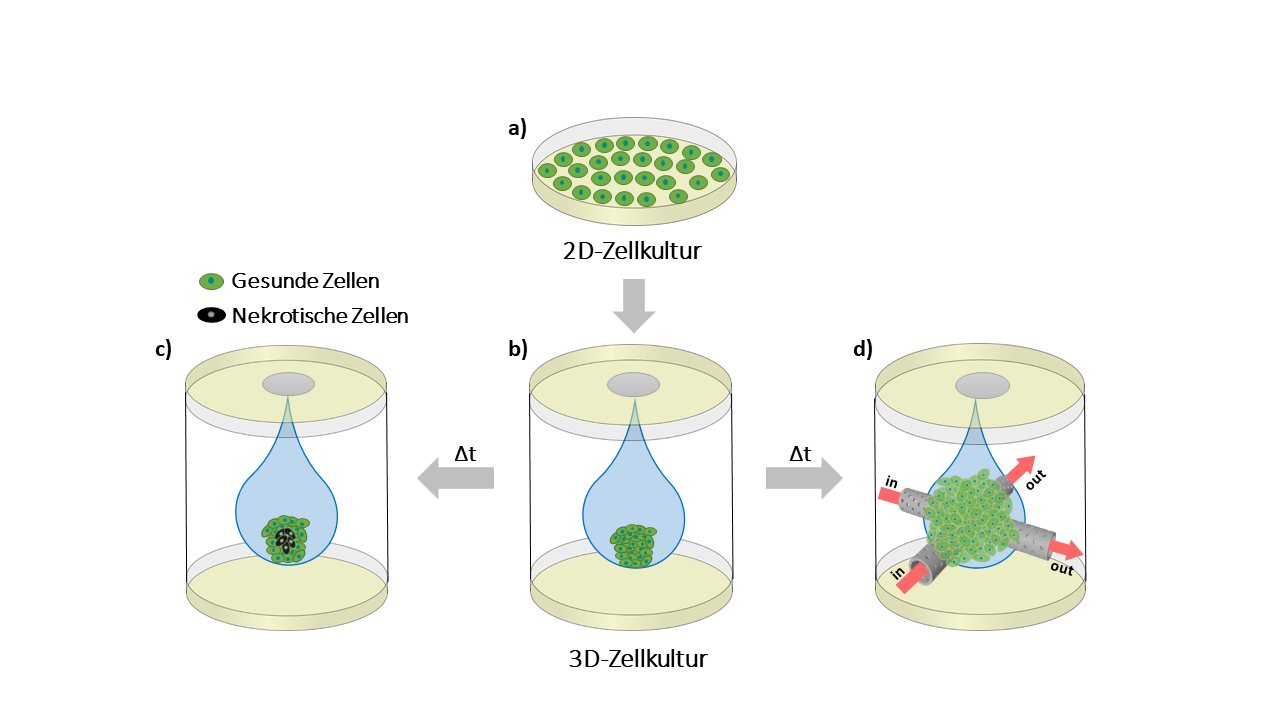

Development of a vascular channel system for 3D tumor spheroids

Our project ‘vascular’ is based on the development and establishment of a biocompatible vascular system for 3D-cell cultures, mainly tumorous spheroids. Using simulations as well as two-photon-lithography, channels are developed and printed in a fine mesh before being cultivated with spheroids. Purpose of the channels is to supply the spheroids, thus preventing the emergence of a necrotic core and sustaining even larger spheroids. This results in an in-vitro cellular model which represents the in-vivo situation to a great extent and supersedes animal testing. Furthermore, in-vitro spheroids are characterized using multiple spectroscopic methods such as IR, Raman, UV/Vis, elastic light scattering and 3D-imaging. In summary, the project follows an interdisciplinary approach, merging fluctuation simulation, 3D-microstructures, 3D-cell culture, physicochemical analytics and statistical analysis.

Contacts:Prof. M. Brecht, M. Bassler, Dr. A. Lorenz, A. Wagner

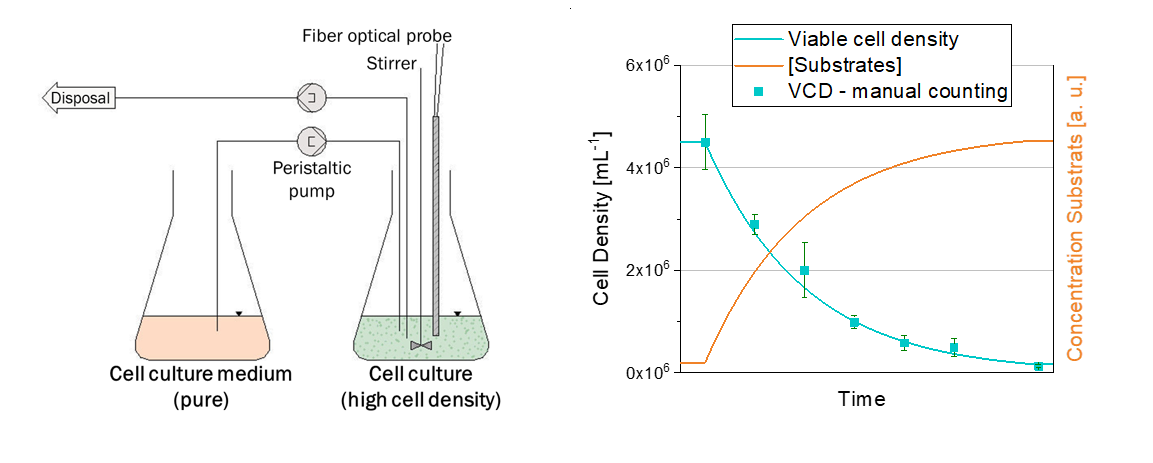

Viazell - Development of a fibre-optic sensor for determining cell viability in bioreactors

Increasingly, drugs are produced in biotechnological processes. Among other things, animal cells are used to produce recombinant antibodies, e.g. for the treatment of rheumatic diseases. For the success of the manufacturing processes, these sensitive cells require careful monitoring by process analytical methods. In the Viazell development project, we are developing a probe technology for the spectroscopic determination of important quality parameters in animal cell cultures together with partners from industry. Using UV/VIS spectroscopy and multivariate methods such as Multivariate Curve Resolution (MCR), critical parameters such as cell viability are to be determined.

Contacts: Prof. K. Rebner, T. Drieschner, Dr. S. Nellinger

Investigation of the potential of spectroscopic methods for monitoring a microreactor for the synthesis of biodiesel (Mittelbauprogramm)

This project aims to investigate to which extent spectroscopic sensors, e.g. near-infrared sensors, can provide valuable information on the process progress of chemical syntheses. Using the example of the production of biodiesel in a continuous microreactor, the yield is recorded directly in the process. For this purpose, the sensor's extensive spectral information is evaluated using multivariate data analysis (MVA) methods. In this way, it should be possible to transmit critical quality parameters to the process control system in order to control the process optimally.

Contacts:Prof. K. Rebner, T. Drischner

Research Projects Spectral Imaging

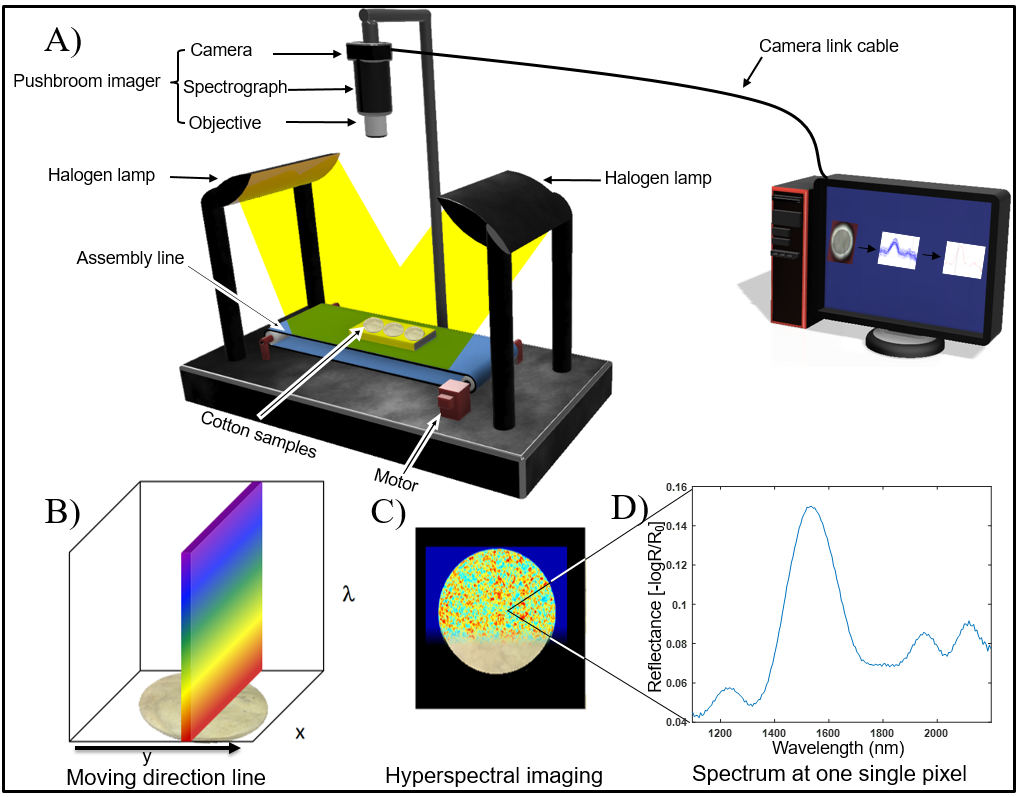

Different types of raw cotton were investigated by a commercial ultraviolet-visible/near infrared (UV-Vis/NIR) spectrometer (210–2200 nm) as well as on a home-built setup for NIR hyperspectral imaging (NIR-HSI) in the range 1100–2200 nm. UV-Vis/NIR reflection spectroscopy reveals the dominant role proteins, hydrocarbons and hydroxyl groups play in the structure of cotton. NIR-HSI shows a similar result. Experimentally obtained data in combination with principal component analysis (PCA) provides a general differentiation of different cotton types. For UV-Vis/NIR spectroscopy, the first two principal components (PC) represent 82 % and 78 % of the total data variance for the UV-Vis and NIR regions, respectively.

Whereas, for NIR-HSI, due to the large amount of data acquired, two methodologies for data processing were applied in low and high lateral resolution. In the first method, the average of the spectra from one sample was calculated and in the second method the spectra of each pixel were used. Both methods are able to explain ≥90 % of total variance by the first two PCs. The results show that it is possible to distinguish between different cotton types based on a few selected wavelength ranges. The combination of HSI and multivariate data analysis has a strong potential in industrial applications due to its short acquisition time and low-cost development. This study opens a novel possibility for a further development of this technique towards real large-scale processes.

Contacts:Prof. M. Brecht and M. Alktash

Sorting of recyclable materials with the help of intelligent & learning hyperspectral camera systems

In the HyperSPEC project old and new analytical methods are combined to develop efficient, innovative and future-proof processes for waste sorting. On the one hand, we rely on proven chemometric methods to process spectral data, such as principal component analysis (PCA), and on the other hand, we use novel methods in the field of artificial intelligence (AI). Here, the use of so-called artificial neural networks (ANN) is particularly suitable. With this, already existing or constantly newly gained knowledge can be taken up by a software, which can thereby continuously develop further. The expertise gained is not limited to the specific problem of waste sorting and we expect this to lead to broad application possibilities of our methods in related and practice-relevant problem areas.

Contacts: Prof. K. Rebner, B. Boldrini, A. Stuhl

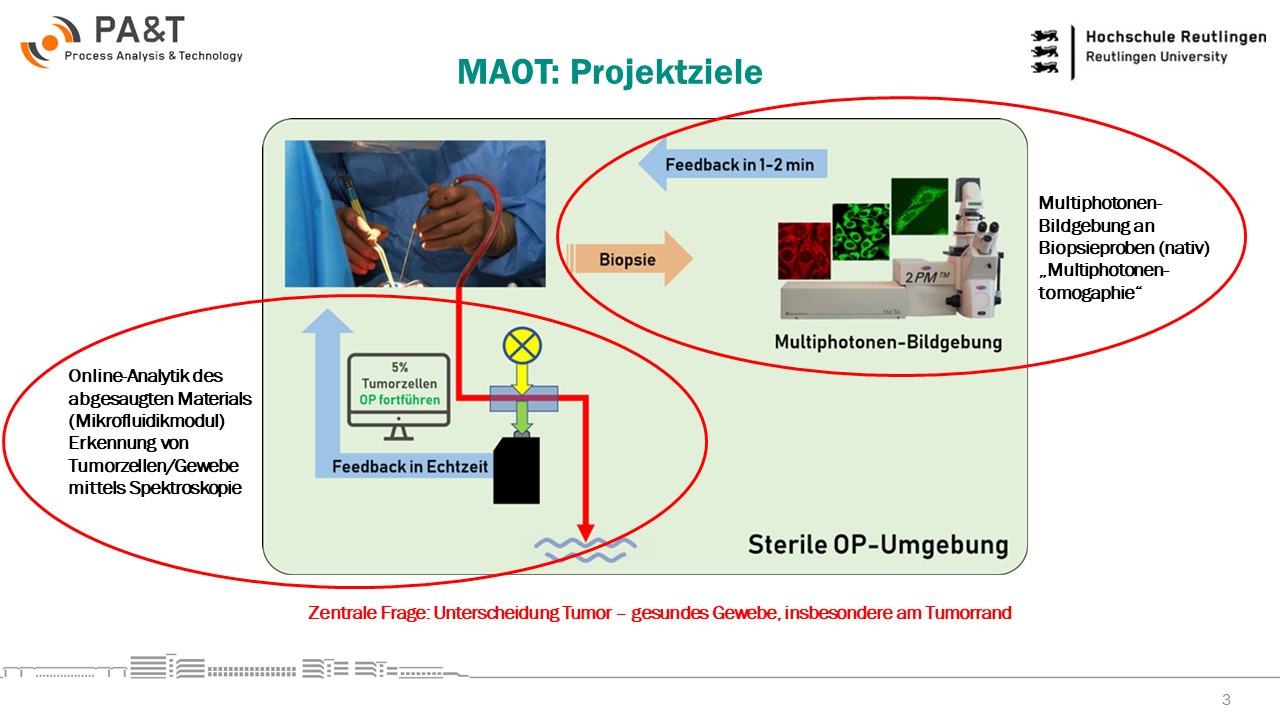

Multiphoton analysis for online tumor margin determination

Cancer is the second leading cause of death in Germany. Surgical interventions to remove tumors are among the common forms of therapy. In order to maintain the function of the organs affected by the cancer as far as possible, it is desirable to specifically remove only diseased tissue. In microscopically controlled surgery, tissue samples are taken during the surgical procedure (biopsy) and colored using various histological methods and examined under the microscope. The samples are sent from the operating room to the pathology department and analyzed there. A result is typically only available after 20-40 minutes, and the surgeon can end or resume the operation to completely remove the tumor. The aim of the project is to develop an analysis method for the rapid determination of the tumor margins during the ongoing operation. In order to obtain a wide range of analytical possibilities, the method should be based on a combination of multiphoton microscopy and online spectroscopy or imaging. The idea of this project is to use cell suspension during the operation to determine the tumor margins.

Contacts:Prof. M. Brecht, Prof. K. Rebner, Dr. A. Lorenz, Mrs. M. Knoblich

Biochip for the optimization of biomaterials

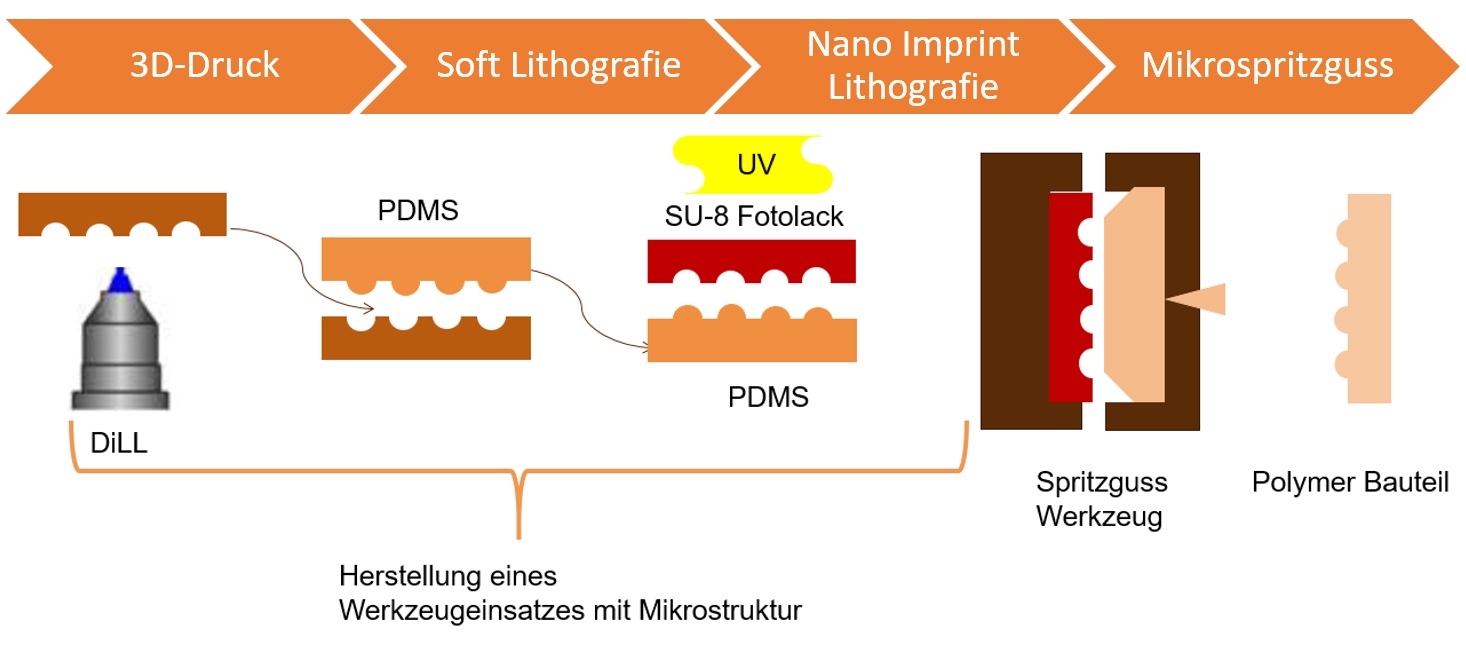

The aim of this project is the development of a biochip for the investigation of biological interactions, especially the reactions of cells on structured and chemically modified polymer surfaces. For this purpose, an injection moulding process has been developed which enables the production of such surface-structured biochips from different polymers.

The process consists of the combination of micro and nano 3D printing with two lithographic impression methods.

In the first step, 3D printing is used to structure and shape the surfaces. Due to the additive manufacturing technology, practically all surface structures can be realized. Only overhanging structural elements have to be avoided due to the subsequent moulding steps. The subsequent moulding of the 3D-print structures results in a structured tool insert which can be used in a subsequent step in micro injection moulding to structure the surface of thermoplastic polymers.

Due to the reusability of the tool insert in injection moulding, the structure can be transferred to a variety of components within a short time. Thus, quantities that would not be possible with the original 3D printing can be achieved within a very short time.

Contacts: Prof. G. Lorenz und Hr. M.Sc. Schneider

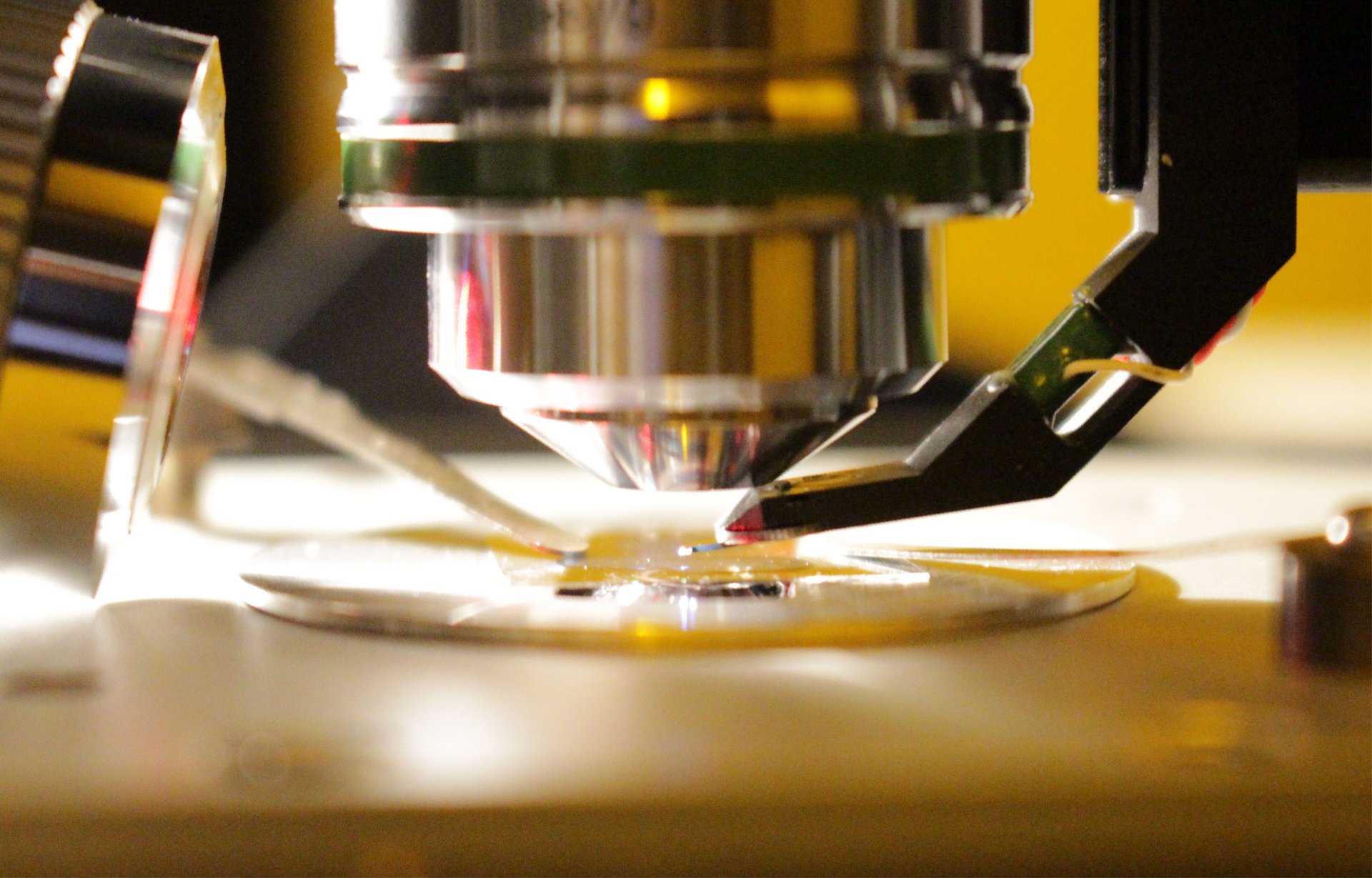

Comparison of different experimental approaches to tip-enhanced Raman spectroscopy

This comprehensive project examined three key microscopes used in confocal Raman microscopy (CRM), focusing on the evaluation of spectral resolution for comparison. Raman imaging techniques using multivariate analysis (MVA) and principal component analysis (PCA) successfully differentiated tissue components with a remarkable accuracy rate of 94%. Surface-enhanced Raman spectroscopy (SERS) comparisons emphasized the importance of uniformity in sample areas. The study also explained the modification of a commercial microscope for tip-enhanced Raman spectroscopy (TERS) and resulted in a reliable "TERS-proven" microscope. Sample preparation techniques for SERS and TERS, including gradient and 3D substrates, were explored, as was the meticulous fabrication of TERS tips. The report concluded with comprehensive TERS measurements that evaluated nanoscale resolution, signal quality, and the influence of tip-to-sample distance. Overall, the aim was to highlight different facets of CRM and provide insights for informed experimental design and potential applications in medical diagnostics.

Contacts: Prof. M. Brecht, A. Mukherjee, Dr. A. Lorenz

Research Projects Polymer Technology

In liquid chromatography, the materials used to date set limitations for high separation efficiency with simultaneous miniaturization. A team of scientists from Duisburg and Reutlingen is now tackling this challenge.

The aim of the project is to significantly overcome these limitations through the additive manufacturing of micropillars in the nanometer precision range, which can be integrated into a microfluidic lab-on-a-chip system as a stationary monolithic solid phase. To this end, the scientists at the Institute for Energy and Environmental Technology and Reutlingen University, Faculty of Life Sciences, want to print the micropillars using two-photon lithography and functionalize the materials used in micro 3D printing for chromatography (e.g. reversed phases, ion exchangers).

Contacts:Prof. G. Lorenz, Prof. M. Brecht, Dr. A. Lorenz

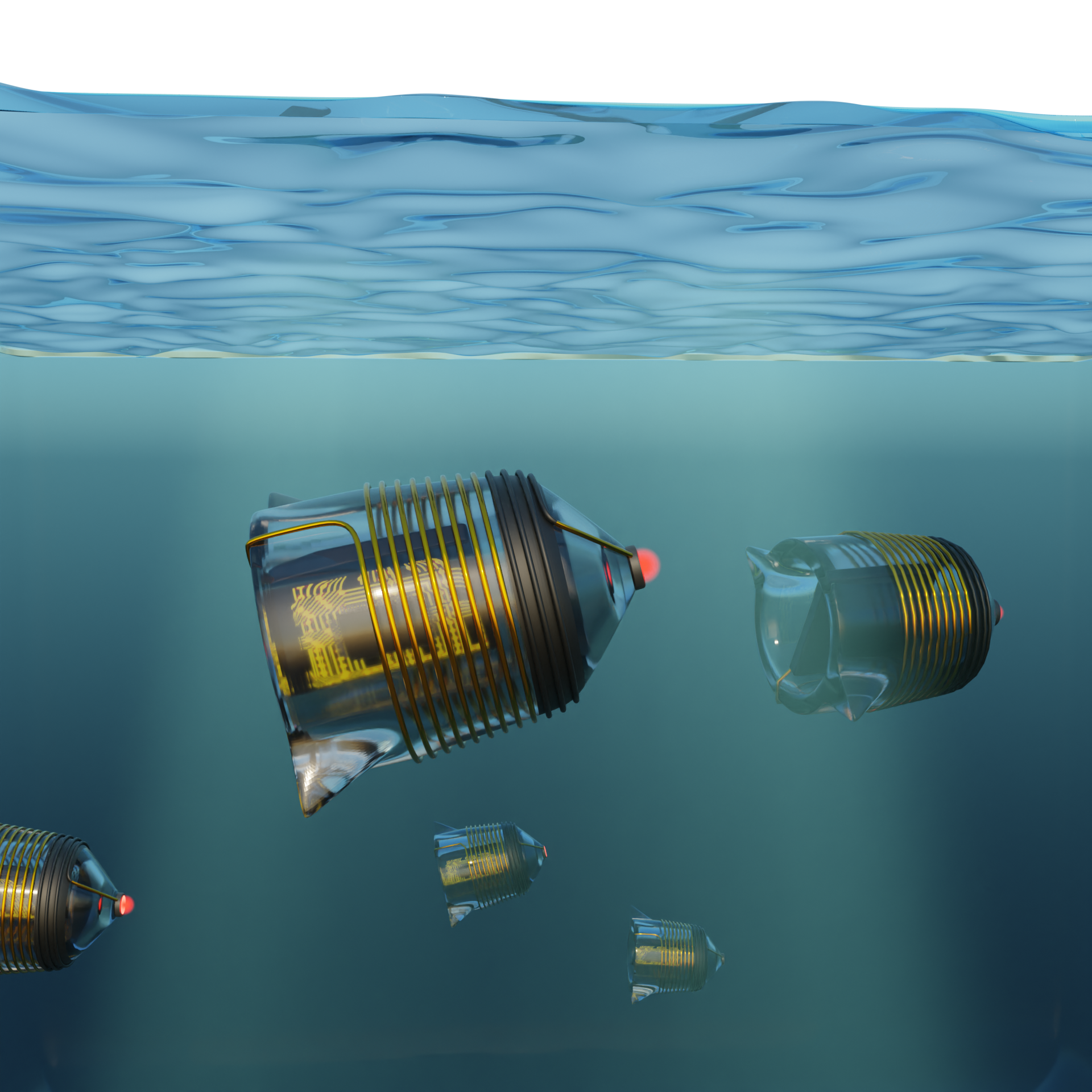

Laser-based one-step process for nanoscale 3D printing of microbots - nanobots

The WILD-Card project focuses on the nano-printing technology of gold for the production of substrates for surface-enhanced Raman spectroscopy (SERS). The Nanoscribe 3D printer, which uses two-photon polymerization technology, is used for this purpose. The manufactured substrates are then verified using Raman spectroscopy to evaluate their potential for use in the commercial SERS market.

Contacts:Prof. M. Brecht and Dr. F. Wackenhut

Biochip zur Optimierung von Biomaterialien

Ziel dieses Projekts ist die Entwicklung eines Biochips zur Untersuchung biologischer Wechselwirkungen, insbesondere der Reaktionen von Zellen auf strukturierten und chemisch modifizierten Polymeroberflächen. Zu diesem Zweck wurde ein Spritzgussverfahren entwickelt, das die Herstellung solcher oberflächenstrukturierter Biochips aus verschiedenen Polymeren ermöglicht.

Der Prozess besteht aus der Kombination des Mikro- und Nano-3D-Druckes mit zwei Lithografischen Abformungsmethoden.

Der 3D-Druck dient im ersten Schritt der Strukturierung und Formgebung der Oberflächen. Aufgrund der additiven Fertigungstechnik lassen sich praktisch fast alle Oberflächenstrukturen verwirklichen. Lediglich auf überhängende Strukturelemente muss aufgrund der nachfolgenden Abformungsschritte verzichtet werden. Durch die anschließenden Abformungen der 3D-Druck Strukturen wird ein strukturierter Werkzeugeinsatz erhalten der in einem nachfolgenden Schritt im Mikrospritzguss verwendet werden kann um die Oberfläche thermoplastischer Polymere zu strukturieren.

Durch die Wiederverwendbarkeit des Werkzeugeinsatzes im Spritzguss lässt sich die Struktur innerhalb kurzer Zeit auf eine Vielzahl von Bauteilen übertragen. Somit lassen sich innerhalb kürzester Zeit Stückzahlen erreichen, die mit dem ursprünglichen 3D-Druck nicht realisierbar wären.

Contacts: Prof. G. Lorenz und M. Schneider

Ausbau der Prozess-Analytical Technology (PAT) angewandt auf die Schmelzextrusion mit Fokus auf Kristalinität/ Phasen-Inhomogenitäten und Verunreinigungen

Die Prozesskontrolle einiger extrudierter Pharmaprodukte erfolgt zur Zeit at-line durch optische Kontrolle. Typische off-line Analytik ist die WAXS und die Lichtmikroskopie. Die Studie hat das Ziel einen Sensor für die Extrusion zu entwickeln, der die Messung des Trübungsgrades erlaubt und der zwischen unterschiedlichen Ursachen der Trübung unterscheiden kann.

Contacts: Prof. G. Lorenz and Prof. K. Rebner

Looking for the needle in a haystack

SKZ and LFZ PA&T of Reutlingen University start collaborative research project for quantitative inline detection of additives in highly filled plastics.

The widespread use of plastics in everyday life is made possible by the use of additives and fillers. Expensive high-performance thermoplastics such as polytetrafluoroethylene (PTFE) have a market share of only 1%, since inexpensive standard thermoplastics such as polyethylene (PE) or polypropylene (PP) are sufficient for most applications due to the use of special additives and fillers. The additive content is essential for the service life and functionality of a component. However, the quantitative detection of the additive content, e.g. for quality assurance, is a great challenge. Especially when fillers are used in high concentrations, inline detection with spectroscopic methods is not possible so far, because the scattering behavior of the fillers prevents spectroscopic detection of the additive. Quantification of the additive content can therefore only be carried out offline using complex methods.

The aim of the research project is to further develop the existing inline measuring systems to enable better detection of the additives. In particular, the measuring range is to be extended to 250 - 2100 nm and the suitable measuring geometry is to be determined on the basis of simulations. By adapting the measuring system and using multivariate data analysis, the spectroscopic quantification of additives in filled plastic melts has to be enabled.

Contacts:Prof. M. Brecht, Prof. K. Rebner, Prof. G. Lorenz and T. Bäuerle

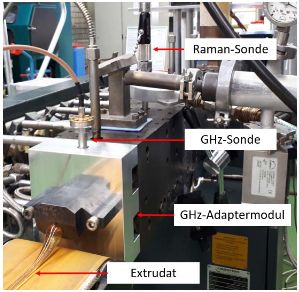

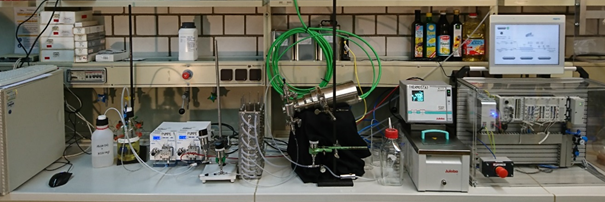

Inline-Kontrolle und Steuerung von Extrusionsprozessen mittels multimodaler Spektroskopie

Inline-Messtechniken zur Kontrolle und Steuerung von Extrusionsprozessen stehen derzeit nur in sehr begrenztem Umfang zur Verfügung und haben sich am Markt noch nicht etabliert. Ziel des Forschungsprojektes “REX-Inspec“ war es daher, neue und kombinierte Inline-Messmethoden zur Kontrolle und Steuerung von Extrusionsprozessen zu entwickeln. Diese basieren auf spektroskopischen Messverfahren sowohl auf der Extrusionsstrecke als auch am Extruderende (Düse).

Inline-Messungen haben den großen Vorteil, dass sie ohne große Zeitverzögerung Daten über den Prozess sowie die aktuelle Produktqualität liefern. Das ermöglicht zum einen eine Qualitätskontrolle in Echtzeit und ist zum andern die Basis für eine automatisierte Prozesssteuerung.

Bei den von der Hochschule Reutlingen entwickelten spektroskopischen Inline-Verfahren handelt es sich UV/VIS-, Nahinfrarot (NIR)-, und Raman-Spektroskopie. Darüber hinaus wurden THz-Sensoren (Universität Marburg) sowie GHz-Sensoren (Fa. hf-sensor, Leipzig) in den Extruder integriert. Um die verschiedenen Sensoren und Messköpfe in den Extruder zu integrieren, wurde dieser mit entsprechenden Bohrungen auf der Verfahrensstrecke sowie mit verschiedenen Adaptermodulen vor der Düse modifiziert. Die verschiedenen spektroskopischen Daten sowie die Prozessdaten des Extruders konnten auf einer von der Fa. GED entwickelten Software-Plattform zusammengeführt und visualisiert werden.

Die Leistungsfähigkeit, Nachweisempfindlichkeit sowie die Vor-und Nachteile der einzelnen spektroskopischen Inline-Messtechniken wurden am modifizierten Extruder am Beispiel von drei verschiedenen Compoundierungs-prozessen sowie der reaktiven Extrusion von Polyurethanen untersucht.

Besonders erfolgreich und vielversprechend ist die Kombination verschiedener spektroskopischer Techniken (multimodale Spektroskopie). Dadurch ist es möglich, komplementäre Informationen über die chemischen und morphologischen Eigenschaften des Systems zu erhalten. Multivariate Analysemethoden, z. B. die Hauptkomponentenanalyse oder multivariate Regressionsmodelle ermöglichen die Extraktion der relevanten Informationen aus den Spektren und führen damit zu einem detaillierten Prozessverständnis. Insgesamt waren viele verschiedene Fachdisziplinen in das Projekt eingebunden, von der Kunststoffverfahrenstechnik (Fa. Allod, Hochschule Reutlingen) über die Spektroskopie und Datenanalyse (Fa. hf-sensor, Hochschule Reutlingen, Universität Marburg) bis hin zur Elektronik- und Softwareentwicklung (GED Gesellschaft für Elektronik und Design mbH).

Der modifizierte und mit Sensoren ausgestattete Extruder der Hochschule Reutlingen steht interessierten Anwendern für Testextrusionen zur Verfügung. Es besteht Expertise sowohl im Kunststoffbereich (Compoundierung, reaktive Extrusion) als auch im Pharmabereich (Hot Melt Extrusion von pharmazeutischen Wirkstoffen in einem Trägerpolymer).

Contacts: Prof. K. Rebner and Prof. G. Lorenz

Dichtwerkstoff-Stack-Konzepte für den Einsatz in Brennstoffzellen

Im Rahmen dieses Forschungsprojektes sollen neuartige Dichtwerkstoff-Stack-Konzepte für den Einsatz in Brennstoffzellen des Typs PEMFC (Polymer Electrolyte Fuel Cell) entwickelt werden. Notwendig ist die Entwicklung eines elastomeren Dichtwerkstoffes, der ein verbessertes technisches Eigenschaftsprofil, höhere chemische Beständigkeiten und eine längere Lebensdauer in Form statischem Langzeit-Dichtkraftverhaltens bietet. Um dieses Ziel zu erreichen werden im Projekt neue Vernetzungssysteme entwickelt und auf EP(D)M angewendet. Zudem sollen Optimierungen im Design der Stackauslegung und des Dichtungsprofils die Effizienz Brennstoffzelle erhöhen.

Contacts: Prof. G. Lorenz and Prof. A. Kandelbauer

Research Projects Surface Design

Aim of the SiliSurfChrom project

The SiliSurfChrom project aims to produce surface-functionalised silica particles reproducibly and with consistent quality. These are characterized by a large specific surface and a high surface coverage with hydrophobic functionalities. In addition, the newly developed particles have an exceptionally uniform (monodisperse) size distribution. As adsorption material for chromatographic separation columns in analytical and preparative reversed-phase high-pressure liquid chromatography (RP-HPLC), they are expected to have a high separation performance for structurally very closely related therapeutically active peptides and a high separation speed for their industrially economical preparative production and analysis.

Contacts:Prof. A. Kandelbauer and M.Sc. J. Steinbach

Innovative Foam Structures for Efficient Lightweight Construction

Modern lightweight materials offer great potential in many industrial applications, but due to their usually pronounced anisotropic load behaviour and low rigidity, they require complex design measures for functionally optimized application. In the project "InSeL" novel cellular lightweight materials with high inherent rigidity are to be developed, which close this functional gap. In a holistic approach, self-contained cellular lightweight materials and composites with inherent scaffolds are developed based on open-pored metal foams. In parallel, a new process is to be developed with which monodisperse polymer foams can be produced by the use of surfactants. This method is intended to substitute the specific manufacturing process of casting models for the cellular lightweight structures and in conjunction with the investment casting process also allow a well-defined and reproducible foam structure.

Contacts:Prof. R. Krastev (Smart Biomaterials Centre) and Prof. G. Lorenz

Treating Osteoarthritis in knee with mimicked interpositional spacer

Polyurethanes with different soft segment and varying diisocyanates will be synthesized in laboratory scale. Reactants will be selected which yield a material with low water uptake, high mechanical stability and high resistance against oxidation and hydrolysis (cause of biodegradation).

To alter the surface properties the “microstructure” (molecular chains) of the material will be modified with a polyurethane which contains hydrophilic segments This results in a material system with a mechanically stable core part with low water uptake and an outer shell with a water-containing surface region. This modification allows an improved chemical modification of the surface with bio-derived molecules in order to facilitate an interaction with the synovia (synovial fluid) in particular hyaluronic acid and to protect the implant from wear.

Contacts:Prof. G. Lorenz and Prof. R. Kemkemer (Smart Biomaterials Centre)